IBERFOIL’s strong commitment to a better world

With the aim of achieving the eradication of poverty, eliminating inequalities and protecting the planet by 2030, IBERFOIL focuses all the efforts of its activity on complying with the agenda set by the United Nations, which is supported by 17 Sustainable Development Goals (SDGs).

The most important objective for the company is people, which is why it dedicates and invests great efforts in training its employees (SDGs 3 and 4) and in providing new opportunities for future generations, collaborating with Vocational Training Centres and Universities in the area (SDG 8).

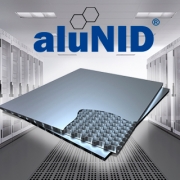

Strongly committed to innovation, the future and industry (SDG 9), it has recently expanded its infrastructures with the new Tension Levelling Line in order to be able to enter new markets with innovative and high-quality products.

On the other hand, it is deeply concerned with the environment and with quality policies based on a sustainable future, carrying out strict controls throughout its production process that guarantee maximum use of the raw material with which it works, aluminium, and therefore ensure responsible production and consumption, both of resources and of the energy used (SDGs 6, 7 and 12).

Furthermore, thanks to the properties of aluminium, it is possible to recycle and reuse the surplus material an infinite number of times without losing its properties during the process. This means that its ecological footprint and environmental impact are drastically reduced as nothing is wasted from this raw material, and everything enters back into the infinite circular economy (SDGs 13 and 15).

There is still a lot of work to be done to achieve the goals set by the UN, but IBERFOIL is confident that through the values it promotes in its workers, the effort and enthusiasm of society as a whole, these goals will be achieved and, to this end, it will continue to work and focus its business strategy on achieving a better world.