THE PRESIDENT OF THE JUNTA DE ANDALUCIA VISITS ALUCOAT AND SUPPORTS ITS INNOVATION AND GROWTH PROCESS.

The company, which has broken the production, turnover and results record this year, is immersed in an ambitious plan for digital transformation 4.0.

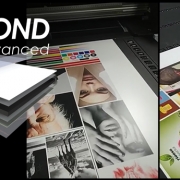

Linares, January 21st. The president of the Junta de Andalucía, Juan Manuel Moreno Bonilla, visited the Alucoat Conversion factory today in Linares, (Jaen). Belonging to Grupo Aliberico, to show his support for the innovation and growth plans, which has been promoting this industrial and technological company for years, specialized in coating aluminium coils between 20 and 500 microns thick for sectors such as food, pharmacy, conditioning and building.

During his visit, the president of Junta de Andalucia was accompanied by the major of Linares, Raul Caro-Accino and was received by the Director of Alucoat Conversion, Jose Manuel González Plaza and the counsellor of Grupo Aliberico , María González Armero.

Since it was privatized by SEPI in 2001 and acquired by Grupo Aliberico, Alucoat Conversion has invested heavily in innovation and technological transformation, which has allowed it to increase the number of customer and portfolio in critical sectors such as pharmaceuticals and sanitary.

This strategy has led the company to beat the production, turnover and results record in the just ended year.

Currently, Alucoat is immerse in an ambitious plan of digital transformation that will standardize its processes to the 4.0 digital standard. This will affect internally to the company and its relationship with customers and suppliers.

Alucoat maintains intact its commitment to Andalusia and the city of Linares, which is based on the determination to continue growing through investment in new facilities and machinery and the creation of new quality jobs.

Nowadays, the company has a workforce of 70 people, 94% of them with permanent contracts. Furthermore, even being an industrial company, half of the directives positions are held by women.

Alucoat is the unique producer of coated aluminium of in Europe up to 1.650 mm wide, which positions the company as the only one in its sector both nationally and in Europe. Currently, Alucoat exports 50% of its production to more than 46 countries.