ALUCOIL North America stands out at AIA 2018

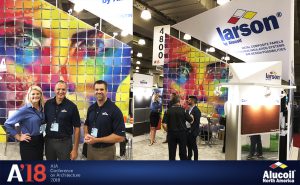

During June 21st and 22nd , ALUCOIL North America exhibited at the AIA National Convention, the most recognized trade show in North America for Architectural Design, taking place at the Javits Center in New York city.

At AIA 2018, ALUCOIL North America’s technical and commercial team had the chance to display ALUCOIL’s innovative and Advanced Materials for the Building Sector, larson ® Aluminium Composite Panels and larcore ® Aluminum Honeycomb Panels.

Since 2012, ALUCOIL North America has participated in this trade show, which brings together more than 800 exhibitors and more than 23,000 visitors. ALUCOIL’s booth has been designed to show the quality, design and wide range of finishes of the larson ® and larcore ® panels, manufactured with unique technology and specifically designed for the Building sector. ALUCOIL North America’s booth was a meeting point for many visitors who showed great interest and confidence in its products, service and quality.

Numerous visitors from all over the globe attended the event and saw the innovative and colorful ALUCOIL stand designed with larson ® by Alucoil ACM. ALUCOIL’s BIM technology was also highlighted and materials such as larson ® and larcore ® A2 brochures were made available to the public.

ALUCOIL North America, maximum innovation and cutting-edge technology in the manufacture of Advanced Materials for architecture