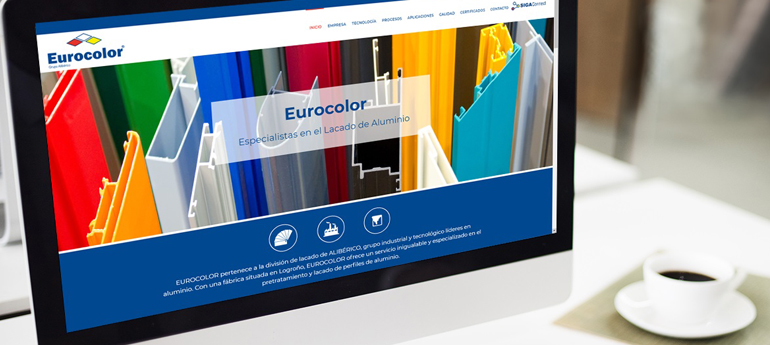

EUROCOLOR launches NEW website

The company specializing in the lacquering of aluminum profiles modernizes its online presence

EUROCOLOR, a specialist in Aluminum Lacquer, presents its new website to be closer to its customers and be a point of reference by publicizing its activity in the aluminum industry. With a modern, clear and precise design, the new EUROCOLOR website responds to the current needs of the market.

Accessible from any place and any device, the new website demonstrates the quality and technology used by the company in each and every one of its processes, as well as its unmatched delivery times through its EUROCOLOR Express service. It also explains the experience and know-how that EUROCOLOR has in the aluminum sector, especially in treatments and high-quality surface finishes for the building sector.

EUROCOLOR is part of ALIBERICO, with more than 45 years of experience in the manufacture of semi-processed aluminum products. Based in Logroño (Spain), EUROCOLOR is the first company in Spain specializing in surface treatments and finishes, offering the widest range of powder paint coatings.

EUROCOLOR, Quality and Service of Lacquered to Measure and in Record Time.

CLEMENTE GONZÁLEZ SOLER, President of Alibérico Group, Awarded for the Most Relevant Economic and Financial Personality of the Year

The award ceremony took place within the framework of the Night of the Economy, an event promoted by El Economista chaired by the Spanish Minister of Economy and Business, Nadia Calviño

Madrid, November 22nd.- Clemente González Soler, founder, owner and president of Alibérico, the industrial and technological group specialized in the manufacture of semi-processed aluminium products, has been distinguished by the newspaper El Economista as the Most Relevant Economic and Financial Personality Award of the Year, for having converted his firm into the first Spanish private group and the first European family group within the aluminium sector.

The award ceremony took place in the framework of the gala Night of the Economy, an event held at the headquarters of CaixaForum, in Madrid, which was chaired by the Spanish Minister of Economy and Business, Nadia Calviño. The call, which reaches its eighth edition this year and promoted by the EcoPrensa, presided by Alfonso de Salas, was attended by numerous personalities of political, economic and social life.

Clemente González Soler founded Grupo Alibérico in 1997, and since its inception it has been characterized by its great capacity for growth, innovation and internationalization, to become one of the world’s leading references in the manufacture of semi-processed and technologically advanced aluminium products. The Group currently comprises 35 companies with 17 factories on four continents, 10 of them in Spain.

The Industrial Group operates in the sectors of food packaging , building, surface treatment, transport, industry and renewable energy. It exports 70% of its turnover to more than 70 countries on 5 continents and directly employs more than 1,200 people.

The jury of the award has also recognized Clemente González Soler as an exemple of entrepreneurship, supported by deeply held principles and values, and his role in the defense and promotion of a strong and independent civil society. This conviction has led him to exercise an active presence in various business associations. Currently, he is a Member of the Board of Directors of the Family Business Institute; and Member of the CEOE Executive Committee.

In the same way, Clemente González Soler turns his experience and vision into different collective projects. For two years, he has been president of the Executive Committee of IFEMA and, as a professor at the EDEM business school and other academic institutions, he has a strong commitment to university education and senior management.

ALUCOAT awarded for 25 years of commitment to the University of Jaen

ALUCOAT has been rewarded and recognized as a collaborating company with the UJA after 25 years of continuous compromise to the Linares and Jaen campuses.

ALUCOAT has been rewarded and recognized as a collaborating company with the UJA after 25 years of continuous compromise to the Linares and Jaen campuses.

The act celebrated last Tuesday, October 30th, was presided over by the rector, Juan Gómez, in the framework of the commemoration of the 25th anniversary of the UJA, in which he was accompanied by the President of the Social Council, Francisco Vañó. “The University of Jaen has become a valuable instrument of social and cultural transformation and a powerful tool for the economic development of the province”, affirmed Juan Gómez.

ALUCOAT has collaborated since its inception with the University of Jaen establishing a strong bidirectional relationship university-company, tightening bonds and approaching the university students to the professional world. ALUCOAT has always bet on young people maintaining a constant collaboration with the UJA based in a recurrent project of internship with the purpose young people can expose their experiences and knowledge acquired during their studies. The UJA collaboration is the main source of personnel integration in ALUCOAT, generating highly qualified personnel.

ALUCOAT, establishing links with the human capital of the University of Jaén.

ALIBERICO Boosts Young Talent

The company is part of the initiative involving universities throughout the Community of Madrid

Impulsando Talento is a project that brings together graduates and companies based in the Community of Madrid to promote youth talent. ALIBERICO brings with other 40 large companies that are part of this initiative, which promotes the recruitment of graduates with the best academic records in companies where they can carry out their professional development.

Leadership and professional development are values that ALIBERICO ratifies with its participation in Promoting Talent, so that “leaving Spain, and the Community of Madrid, is in any case an option and not an obligation”, in the words of the president of the Community, Ángel Garrido, during the presentation of the project.

ALIBERICO, commited to People.

This Halloween, ¡cook with Alibérico Food Packaging!

Alibérico Food Packaging’s Palco® containers will help you preparing stunning cupcakes

Steps to make chocolate dough

Prepare the aluminium baking moulds of Palco ® and preheat the oven to 180º.

- Pour a few drops of lemon juice into 200ml of milk.

- Melt 250g of butter in bain-marie and add 150g of dark chocolate for desserts.

- Sift 200gr of flour, a pinch of salt and a sachet of yeast.

- Whip the chocolate and butter and gradually add 100gr of sugar. Then add 2 eggs, milk with lemon, a teaspoon of vanilla essence and flour.

- Pour ¾ of the mixture into the Palco® moulds and bake for 25 minutes.

Steps to make pumpkin buttercream

Boil in the microwave small cubes of pumpkin in our Palco® microwave containers. You can read tips for use here.

- Whip 250gr of butter at room temperature and gradually add 250gr of icing sugar until a homogeneous dough is formed.

- Sprinkle with cinnamon, cocoa and pumpkin puree and whip for 30 seconds and with the help of a piping bag place the mixture on top of the cupcakes. Enjoy!

Alibérico Food Packaging, High Quality for the most demanding markets.

ALUCOIL backs “Mirando al Futuro” from Miranda de Ebro

Being supported by ALUCOIL, several investors and different multinationals have been met in the conferences held in Miranda de Ebro.

ALUCOIL, Leader on Advanced Materials for the Building, Transport and Industry, sponsors the Corporate Congress “Mirando al Futuro”, organized by the council of Miranda de Ebro and attended by investors, institutions, enterprises and representatives from different fields that want to invest in Miranda, as ALUCOIL does.

Aitana Hernando, Mayor of Miranda de Ebro and Roberto Martínez de Salinas, Director of “Miranda Empresas”, the municipal office for the corporate development of the city, have introduced this Event, which is thought to be an “encounter for Spanish entrepreneurs to identify Miranda as an ideal place to invest”, as the Mayor’s told. Since its establishment in 1996, ALUCOIL has invested and growth itself continuously. With its expansion and creation of new companies, as ALUCOIL Systems, the employment and economic success in Miranda de Ebro have been increased.

This meeting has counted on the help of ALUCOIL, with the aim of revolutionize and encourage the creation of jobs as well as the business establishment in the city.

ALUCOIL, committed to Innovation and Constant Improvement.

Insulax® IP, the best acoustic and thermal insulation for sandwich panels.

Insulax® IP is especially designed for the production of panels with PUR or PIR foam.

Alucoat, specialist in coated Aluminum Coils develops insulax®, intended for the production of insulation panels for ventilation ducts. Insulax® is one of our more versatile products, as is a perfect barrier to light, moisture and water, moreover it guarantees a perfect adhesion to PUR and PIR foams.

The excellent properties of insulax® provide to be ease to be molded, which makes it the best choice in special applications. It can be supplied embossed or smooth. Alucoat develops this product like an excellent acoustic and thermal barrier.

For those markets with high hygienic requirements such as hospitals, food industry or pharma, Alucoat develops insulax® IP +, with a special antibacterial coating specifically designed by our R&D department.

Alucoat, high quality for the most demanding markets.

ALUCOIL overcomes successfully the Standard BS 8414

The British Standard Institute (BSI) tests the fire response of external cladding systems.

ALUCOIL, worldwide Manufacturer of Advanced Materials for Building, Transport and Industry, has completely achieved the technical requirements of the British Standard BS 8414, which evaluates the fire reaction in external cladding systems.

The British Standard BS8414 has checked this system with larson® FR 405 panels, which have exceeded the requirements of the BR 135, developed by the Building Research Establishment (BRE). This trial evaluates the fire spreading in a cladding system, simulating a conflagration in an apartment and reaching the façade through the window. The systems used with Larson® FR 405 panels, overcomes it successfully.

ALUCOIL, committed to the highest Quality and Security types.

Quality snacks with IBERFOIL

IBERFOIL aluminium coils are used as packaging for a wide range of food products

IBERFOIL manufactures all its products under the highest quality requirements. Thus, the excellent composition of IBERFOIL aluminium foil allows its pretreatment for final use in products intended for audiences of all ages.

With special attention to food sector and thanks to the highly hygienic materials used in the lamination process, IBERFOIL is the ideal material to wrap the snack of the youngest. IBERFOIL aluminium impedes the growth of bacteria and other harmful organisms.

Therefore, IBERFOIL foil is not only used to wrap the sandwich of children and adults, but is also used as a packaging for chocolates and candies, baby food seals or packaging of paps, among others.

IBERFOIL, Quality and Safety for the most demanding markets.